SA Steam to Liquid

4 Inch Diameter 6 Inch Diameter 8 Inch Diameter 10 Inch Diameter 12 Inch Diameter 14 Inch Diameter 16 Inch Diameter 18 Inch Diameter 20 Inch Diameter 22 Inch Diameter 24 Inch Diameter 26 Inch Diameter 30 Inch DiameterWA Liquid to Liquid

4 Inch Diameter 6 Inch Diameter 8 Inch Diameter 10 Inch Diameter 12 Inch Diameter 14 Inch Diameter 16 Inch Diameter 18 Inch Diameter 20 Inch Diameter 22 Inch Diameter 24 Inch Diameter 26 Inch Diameter 30 Inch DiameterMOUNTING

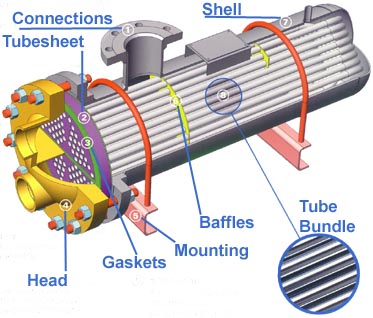

Saddles attached with standard units for quick & easy mounting

BAFFLES

Punched baffles with minimum clearances between tubes assures correct fluid flow and minimized bypass.

SHELL

Welded shell protected with high quality paint for corrosion resistance.

TUBE BUNDLE

Stainless steel tubes allow for strong, durable performance over a wide range of applications. Unique tube bundle layout minimizes buildup problems at the edges and optimizes media flow in the unit.

CONNECTIONS

Standardized sizes for easy assembly. Additional thread and surface protection for clean installation.

TUBESHEET

U-bend tubes expanded into tubesheet allow for tube expansions and contractions due to thermal fluctuations.

GASKETS

High quality compressed fibres (reusable).

HEAD

Standard cast-iron or steel head for heavy duty services (also available as a spare part).

SEC Shell and Tube Heat Exchangers

The Shell and Tube (u-tube) is the most common type of heat exchanger used in the process, petroleum, chemical and HVAC industries, it contains a number of parallel utubes inside a shell. Shell Tube heat exchangers are used when a process requires large amounts of fluid to be heated or cooled. Due to their design, shell tube heat exchangers offer a large heat transfer area and provide high heat transfer efficiency.

There are many different types or designs of shell and tube heat exchangers to meet various process requirements. Shell and Tube heat exchangers can provide steady heat transfer by utilizing multiple passes of one or both fluids. SEC shell and tube heat exchangers come in two (2) and four (4) pass models standard, and multi-pass custom heat exchanger models.

Shell and Tube heat exchangers use baffles on the shell-side fluid to accomplished mixing or turbulence. Without the use of baffles, the fluid can become stagnant in certain parts of the shell. If you have any questions about how shell and u-tube heat exchangers will benefit your application, contact us.